INNOVATEST designs and manufactures, primarily, load cell based, closed loop hardness testing machines. To understand the great advantages of the closed loop systems over dead weight systems, particularly in hardness testers, one should understand the difference between both systems.

Another key component in hardness testing technology is the Optic or vision system. Optics are often the root cause of limitations in the hardness testing field. INNOVATEST Engineers have developed the most advanced optical imaging systems for Vickers, Brinell or Universal machines, but for less demanding markets we do offer highly advanced analogue and electronic microscopes to address these limitations.

Located in the south of the Netherlands, close to the technical universities (TU) of Aachen, Eindhoven and the Zuyd University of Applied Sciences. It’s here where new designs, new technologies and state-of-the-art firmware and video indent measuring systems for hardness testing machines find their roots.

3 or 4 disciplines come together in most hardness testing instruments. A team of mechanical, electronic, optic and software specialists are working continuously to develop new products that simplify hardness testing procedures or make an even better fit to user requirements.

The INNOVATECH R&D team develops and designs its own hardware and firmware applications. All technology used in the NEXUS and NEMESIS series are products of the masters in our R&D facilities, while all electronic boards and high tech components are manufactured in The Netherlands or world wide, by top class sub contractors.

INNOVATECH develops innovating technology for hardness testing systems. The R&D team also focuses on customized solutions, allowing the user to specify a hardness tester that fits perfectly for a particular job.

Ask our sales team for more information on ‘’fit for purpose’’ hardness testers.

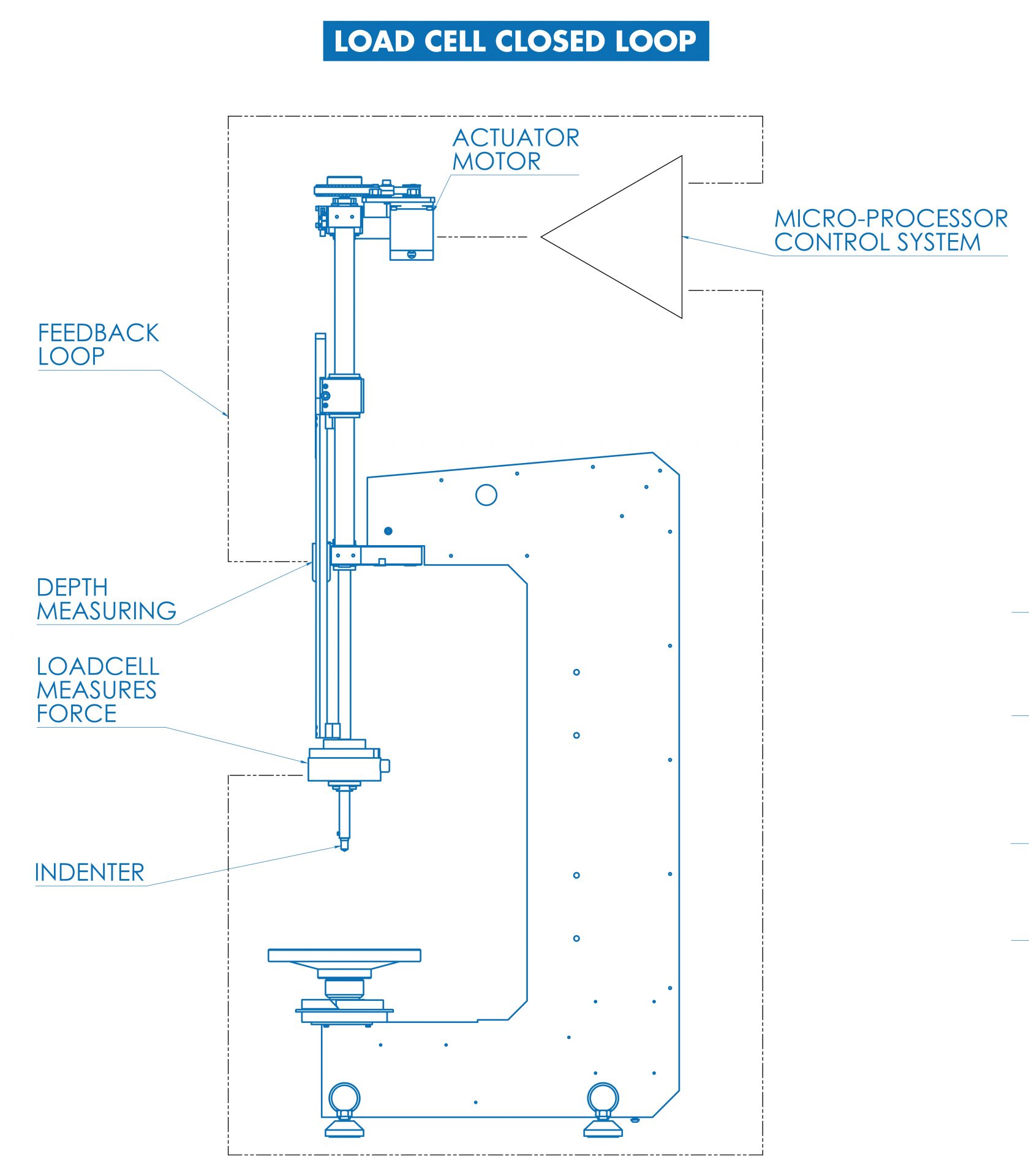

Measuring force in mechanical constructions became important in the early days of industrialization. Around 1940, a Strain gauge load cell was invented. A load cell is a transducer (sensor) that measures force, and outputs this force as an electrical signal. Most load cells use a strain gauge to turn material deformation/force in to an electric signal.

During the 1950s, load cells were implemented in tensile & compression testing machines. The load cell would most ideally be mounted just before or as close as possible to the contact point with the workpiece. The electronic system is designed to use the feedback to adjust the force application mechanism (motor) to apply only the desired force. Closed-loop systems work so well that today all electronic tensile/compression instruments exclusively use closed-loop control.A closed-loop system can constantly measure the test force being applied, and also the components used in a closed-loop system inherently lend themselves to a much simpler design than a dead-weight system. As mentioned on the DEAD WEIGHT systems page of this website, dead-weight systems require levers, pivots and other friction-inducing components to function efficiently.

In a hardness tester, the indenter, the only part of the force system in contact with the test sample, is the most important element for a correct hardness measurement. To eliminate the effect of mechanical imperfection, mechanical moving or other disturbance that could affect the test force, the load cell should be installed as close as possible to the indenter.

Only in this way the real advantage of load cell based, closed loop systems come to their maximum force accuracy. Load cells placed on other positions in the hardness testers mechanical force actuator, rapidly lose most of their advantage over traditional dead weight systems.

INNOVATEST engineers have designed unique non-commercial load cells and force application systems that are the heart of each machine. Nearly all INNOVATEST hardness testers measure force at the indenter mount location to assure the maximum benefits of closed loop technology.

Advantages of closed loop system:

High accurate test forces

Force feedback assures correct force is applied

Wide range of test forces not depending on mechanical limitations

Faster test procedures

Reduction of mechanical parts comparing to dead weight systems

Simple electronic calibration procedure

Disadvantages of a closed loop system:

More expensive than a dead weight system

Requires electricity

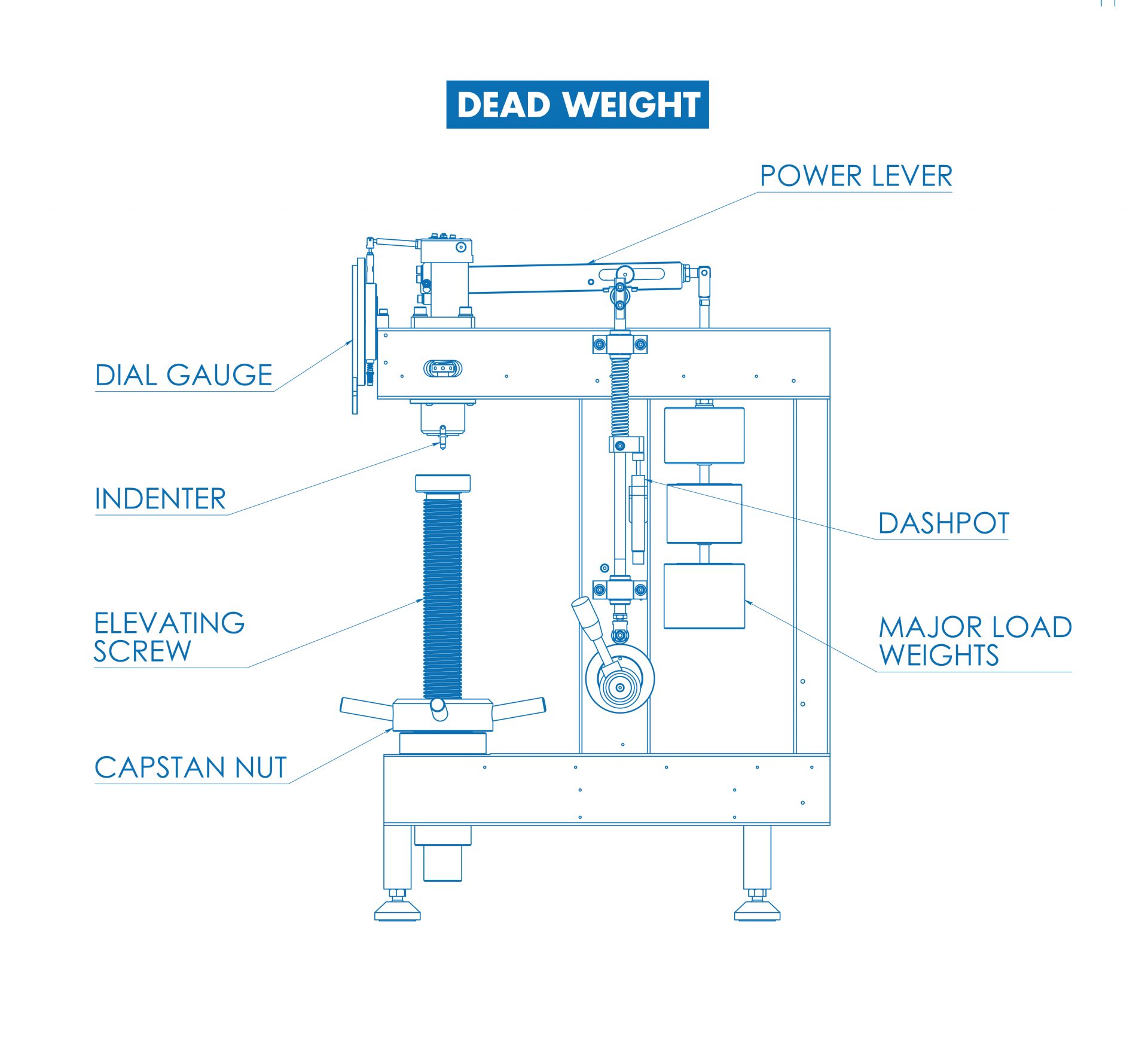

Since early 1900 when the use of hardness testing of metals came as a measure to assure quality (a certain hardness of steel), hardness testing instruments have used dead weights to apply the required test forces.

The reason for this was fairly simple, because dead weights are relatively inexpensive and easy to manufacture to the degree of accuracy required by commonly used test methods.

The problem of deadweights, however, is that the force must be applied to the test piece through a lever structure, with a large number of moving parts, to eventually a small indenter. Transferring the dead-weight force to the tip of a small diamond or ball indenter, for instance 150kgf main load used for a Rockwell HRC test, is difficult to accomplish. The large size and mass of a 150 kg weight would not fit in a handy instrument so it required designers to use smaller weights with levers to intensify the force to the desired levels.

The problem just gets bigger if the force increases to 3000kgf for Brinell measurements, but dead weight systems are also a challenge for designers for low force hardness testers going down to for instance 1gf.

Levers require pivots, guides, bearings and other friction-producing parts that cause force application instability.

Although it is possible to control these sources of error, any friction point in the system will eventually have a negative effect that slowly increases during the lifetime of the instrument. It is also not easy to control a dead weight application in a dead-weight system. Because the dead weight must be moved to apply the test force, stopping it quickly without overload and oscillation is problematic. Many older testers use dashpots (oil filled dampers) to control the application; however, these dashpots where source of problems on their own (oil leaking, wear & tear on the sealings, tempurature effects). In later designs dashpots were replaced by motors.

Although this eliminates some dashpot problems, the need to perform tests quickly makes motor speed critical, and as a result, force overshoot and oscillation are frequent problems. The motorized dead weight testers are also slow working machines, not really suitable for production. It is assumed that dead weight originated forces remain consistent as each test is performed. But it remains to be an assumption, the reality shows plenty of problems.

Because there is no control on the eventually applied force, you could speak of an open loop, force application system;

Advantages of a dead weight (open loop) system:

Easy to manufacture

Low cost to manufacture

Analogue systems require no electric connection

Disadvantages of a dead weight (open loop) system:

No feedback on actual supplied test force

Temperature and environment sensitive

Low performance on Gauge repeatability and reproducibility

Complex & service sensitive mechanical force application system

Wear & tear on mechanics on a longer term

Relative high maintenance cost

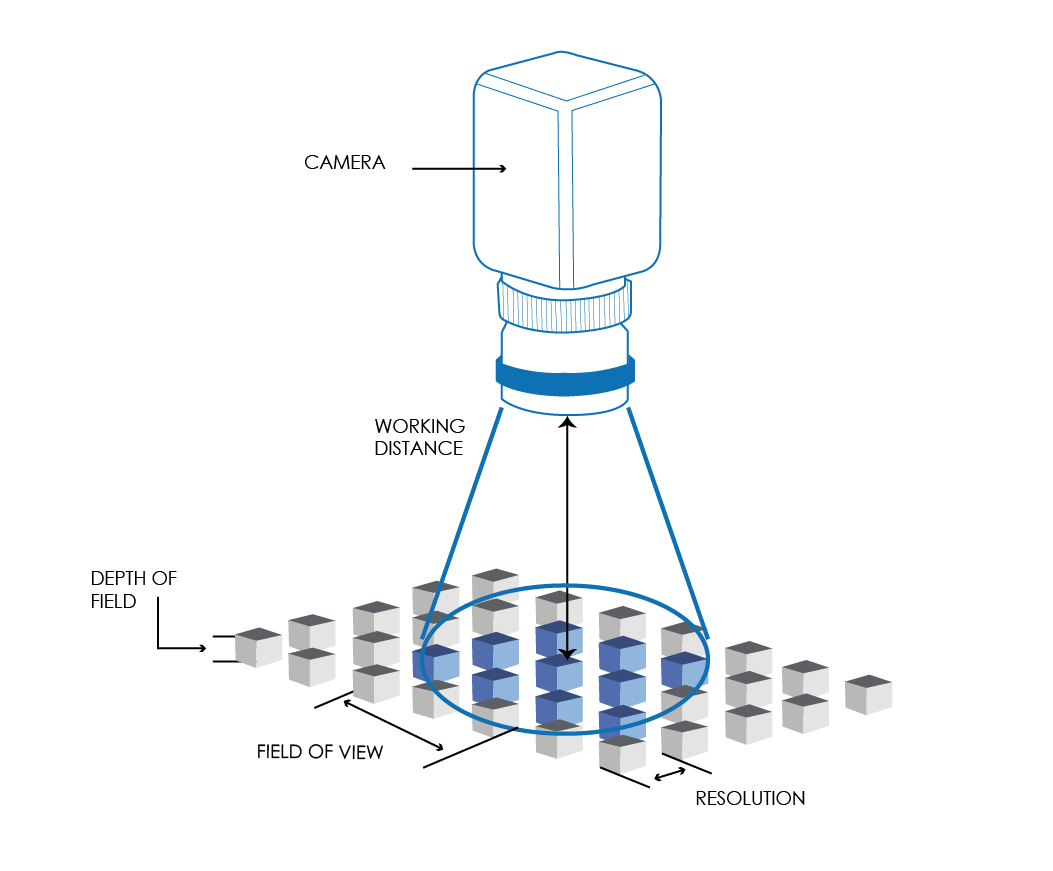

According to the Automated Imaging Association (AIA), machine vision encompasses all industrial and non-industrial applications in which a combination of hardware and software provide operational guidance to devices in the execution of their functions based on the capture and processing of images.

Machine vision helps solve complex hardness testing tasks reliably and consistently

Though industrial computer vision uses many of the same algorithms and approaches as academic/educational and governmental/military applications of computer vision, constraints are different. INNOVATEST machine vision is an integrated part of our hardness testing automation and combines optical systems with refined algorithms for indent measurement, work stage overview and workpiece recognition.

We use cameras with high-speed frame rates and a variety of resolutions up to 18 megapixels, automatic indent and workspace zooming systems. Ultra Bright ringlight technology, LED panels and sophisticated optical filtering methods to refine and ultimately provide the best possible hardness measurement.

For less demanding requirements

While most of the INNOVATEST hardness testing machines make use of sophisticated ultra-high resolution industrial camera systems, with LED ring light or LED panel lights, our more basic models like the FALCON 400 and 450 make use of a proven concept of a metallurgical microscope with a LED based Köhler illumination.

Köhler illumination is a method of specimen illumination used for transmitted and reflected light (trans- and epi-illuminated) optical microscopy.

Köhler illumination acts to generate an even illumination of the sample and ensures that an image of the illumination source (for example in the early days a halogen lamp and nowadays LED lamp filament is not visible in the resulting image. Köhler illumination is the predominant technique for sample illumination in modern scientific light microscopy.

It requires additional optical elements which are more expensive and may not be present in more basic light microscopes.

INNOVATEST hardness testers can be supplied with external desktop computers or workstations. We leave it to your consideration as long as the computer supplied meets the minimum requirements to operate our machines properly.

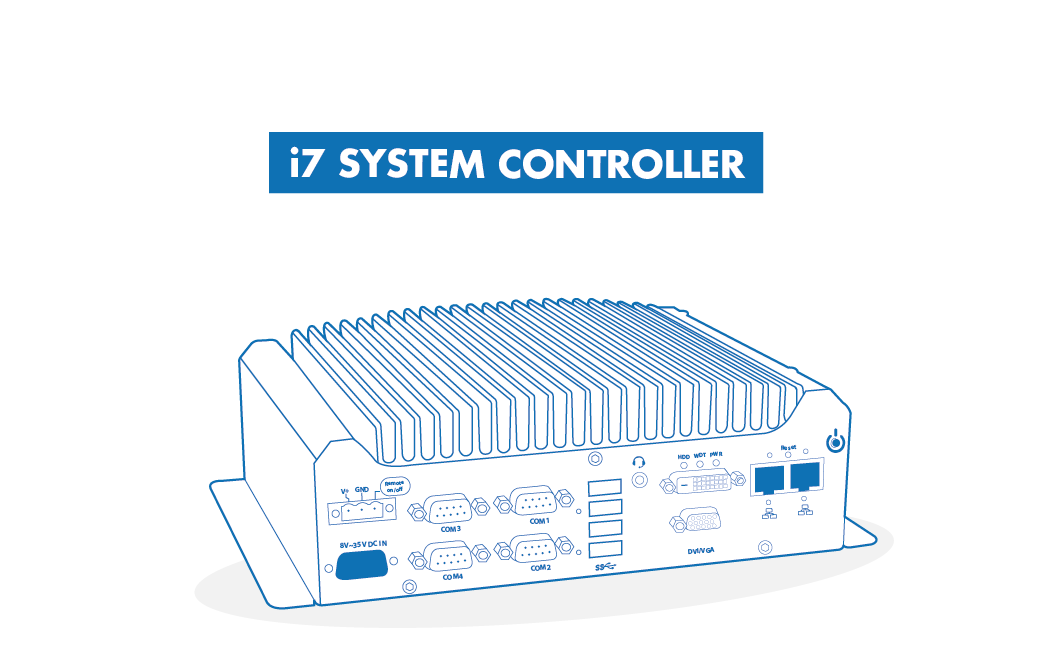

INNOVATEST strongly recommends the use of our standard embedded Industrial Windows controller, let us explain why:

Benefits of an Embedded Industrial Computer

The embedded industrial computer plays a crucial role in the fields of pharmaceutical, medical, food, service industries and the military, to name only a few. Here’s a closer look at some of the superior advantages that embedded industrial computers have over their general desktop or workstation counterparts;

Performance efficiency – In an embedded industrial computer, there is generally a single function for that device. For example, an embedded industrial computer for a traffic signal matrix has the hardware and software dedicated to the proper functioning of that particular purpose alone; hence there is an optimization of what the product can do. You need to ask yourself the question, would you wish to operate a rocket launcher from a desktop work station that has word, excel or games installed? No? At Innovatest we have the opinion that machines and or other quality equipment should be operated from a controller that has one task only, excellent machine performance with high reliability.

Product reliability – Given that an embedded industrial computer is potentially exposed to harsh conditions, and is certainly relied upon to accomplish its task without failure, manufacturers will often add certain features such as an SSD, for fast, reliable data storage, a watchdog timer and design it for fanless operation to eliminate the risk of failure due to moving parts or overheating. Mechanical heat sink as applied in all Innovatest machines eliminates any heat problem.

Durability – Many embedded industrial computers are used directly in factories and other harsh environmental settings which may not only expose them to harsher conditions, but also involve situations of rough handling for these electronics. Embedded industrial computers, depending on their use, are built to withstand fairly severe environments. They can be made to absorb stationary shocks or falls, remain functional even when in transfer via vehicles and are due to their location protected from exposure to moisture and dirt such as by conformal coating of the motherboard.

Longer product life cycle – For most embedded industrial computers, the regular life span of a model is estimated at approximately seven to ten years. Manufacturers design their boards with long life chipsets, assuring that the unit is meant to last. This is 3x better than the life span expectation of desktop work station.

Customizable features – Compared to general-purpose computers, which have an array of basic functions and features that cater to most office needs but have no use in industrial equipment, an embedded industrial computers has 2 main functions only. These are operation, control and data collection of industrial equipment through the specialized software to operate such equipment. With either one of these purposes in mind, nearly anything can be done with the hardware, then the OEM manufacturer, like Innovatest can further customize the unit to accommodate the needs of their particular industry or job by installing their proprietary software like IMPRESSIONS™.

INNOVATEST hardness testing equipment has Embedded Industrial Computers as standard controllers on board of all our IMPRESSIONS™ operated hardness testers.

So, can INNOVATEST IMPRESSIONS™ software run on a standard Hewlett Packard, Dell, or another A class desk top work station? Yes it can, we just don’t recommend it, for the above reasons.